Siemens Gamesa seeks environmental fix for wind turbines ahead of rivals

In both business and journalism, the same main rule applies: It's all about being the first with the latest.

For Siemens Gamesa, this principle seems to have been turned on its head – at least when it comes to launching recyclable wind turbine blades as the OEM announced Tuesday this week, four months after the big announcement from rivaling Vestas about research project Cetec, which aims to make recyclable composites from roughly 2030.

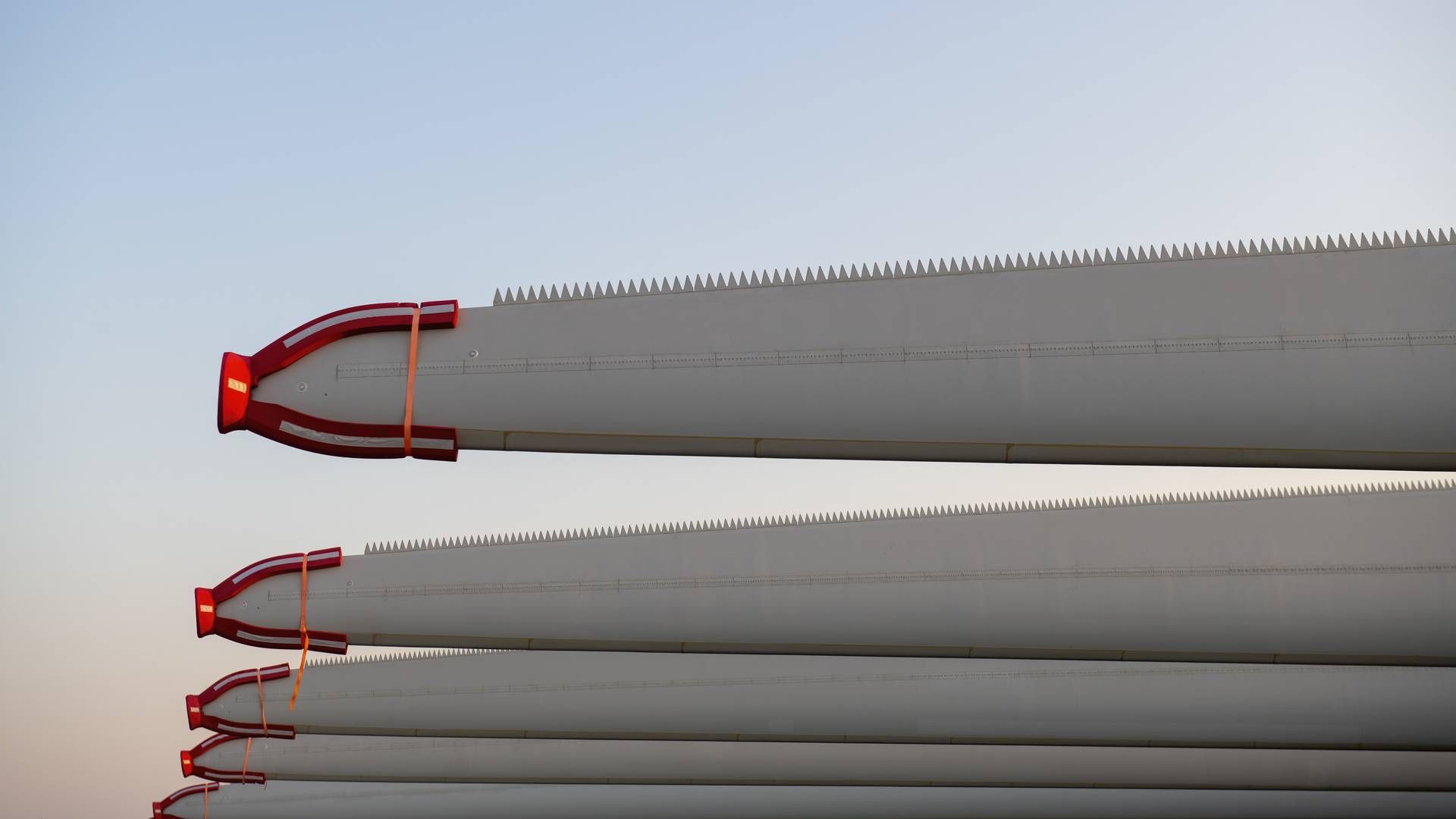

As Vestas was enjoying headlines and the goodwill of the world back in May, Siemens Gamesa was quietly building something else at its blade plant in Aalborg, Northern Denmark: actual recyclable blades – not tinkering with a concept that could manifest ten years in the future, but rather a component set to be shipped a few hundred kilometers south for installation at RWE's offshore wind farm Kaskasi.

"It's important for us to put action behind words. When we announce something such as this, we want to be sure we have tested the product and will be able to quickly supply completed, high-quality blades to customers," says Torben Bang, Siemens Gamesa's country manager for Denmark and chief commercial officer of the group's service division.

"A bird in the hand is worth two in the bush," Bang says.

French legal requirement from next year

Even though the news is finally out, details on the new blades' origins remain sparse. Whereas Vestas' undertaking began in the spring of 2016 in cooperation with the Danish Technological Institute and has now gotten epoxy producer Olin on board, Siemens Gamesa says its development had only been underway for "less than a year", while any potential partners are undisclosed.

However, that marketing such blades is a matter of haste is clear – not only because of the blemished public relations value of photographs showing heaps of blades dumped in landfills; also because the industry risks being overtaken by state policy.

Several nations such as Germany have long made dumping spent blades illegal. Meanwhile, the French government further tightened legislation on the matter last year. Effective from July 1 next year, 90 percent of a wind turbine's total mass, including at least 35 percent of the rotor and epoxy-laminated blades, must either be repurposed or recycled – a difficult task of compliance for conventional blades.

Beyond RWE, two other customers have already signed on to receive Siemens Gamesa's new product, and both of these are active on the French market. Besides state-owned utility Électricité de France, the country's undisputed main offshore wind player, German utility Wpd, which develops wind power both on land and at sea in France, has announced its plans to deploy the OEM's new blade.

Comparable to the car

Bang says the issue basically centers on the intersection of climate and commerce because the climate-friendly status of wind turbines is no given matter.

"A clever person told me a few years back that the wind turbine industry would soon become an environmental burden. He relayed an anecdote about how the automobile was first seen a pure marvel when first invented because it removed all the pollution horses had the habit of dropping behind themselves when they were used for transportation in cities," the service COO says:

"Back then people didn't imagine that cars would one day become the problem. The point was that if we don't figure out what to do with thousands of used blades, then we'll be replaced one day with something cleaner than wind turbines."

Wants to be the solution

Customers are already starting to raise their standard for sustainability. For instance, Siemens Gamesa's largest customer for offshore wind turbines, Ørsted, introduced an immediate ban on landfilling end-of-life blades in June this year – and despite such actions clearly circumventing public policy, suppliers are nonetheless obliged to comply if they want retain customers.

Although behind the business, there's also a softer aspect of this development:

"We have long had a burning desire to remove the hitherto environmental challenge of blades. As a company – and as a sector, I think it's fair to speak on behalf of – we are enormously focused on not being a problem because we actually want to be a solution," Bang states.

Siemens Gamesa launches world’s first recyclable turbine blade for offshore use

Siemens Gamesa to build recyclable turbines from 2040

Ørsted bans landfilling turbine blades

Related articles

Siemens Gamesa to build recyclable turbines from 2040

For subscribers

Ørsted bans landfilling turbine blades

For subscribers

.jpg&w=384&q=75)